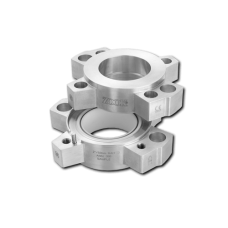

PTFE sleeve on all wetted surfaces of the rupture disk holder inlet, ideal for corrosive applications and reducing the effect of product build-up.

The PTFE Sleeved holder utilizes a Teflon Encapsulated Viton O-Ring as standard. The O-Ring seal prevents the process media getting into contact with the bite-ring outer seal prolonging the life of the holder. ZOOK’s unique double seal prolongs the life expectancy of the holder.

- Ideal for corrosive applications and reducing the effect of product build-up

- A good cost effective alternative to exotic materials

- PTFE sleeve on all wetted surfaces of the rupture disk holder inlet

- PTFE sleeve is available on the inlet only, and outlet can be Fluoropolymer Teflon Sintered (FS) coated

- The ZOOK PTFE sleeved holder utilizes a Teflon encapsulated Viton O-Ring as standard. The O-Ring seal prevents the process media getting into contact with the bite-ring, this prolongs the high performance of the holder

- PTFE sleeve is available for ZOOK flat seat series reverse acting disk holders in sizes from 1” (25 mm) through to 8” (200 mm) ASME Class 150

- The operating temperature range for the PTFE sleeve is -20ºF to 450ºF (-29ºC to 232ºC)

- The ZOOK design utilizes a mechanical lock to engage Teflon for a rigid assembly

- PTFE sleeves are not torque sensitive and follow standard holder torquing procedures